insect mesh for air bricks

Latest articles

insect mesh for air bricksIron products are common metal products in life. Iron products appear everywhere in our life, but there is a big problem in using iron products. Iron products will rust, and when rust occurs, it will affect the use and appearance of iron products. Adding non-metallic coating: clean, dry and coat the surface of iron and steel products with a layer of protective materials, such as oil, mineral grease, rust-proof grease, plastic and lacquer.

...

insect mesh for air bricks 【insect mesh for air bricks】

Read More

insect mesh for air bricks

Post time: 01-03-23...

insect mesh for air bricks 【insect mesh for air bricks】

Read Moreinsect mesh for air bricks

...

insect mesh for air bricks 【insect mesh for air bricks】

Read More

insect mesh for air bricks1. Electroplating process control

...

insect mesh for air bricks 【insect mesh for air bricks】

Read Moreinsect mesh for air bricks

...

insect mesh for air bricks 【insect mesh for air bricks】

Read More

insect mesh for air bricks...

insect mesh for air bricks 【insect mesh for air bricks】

Read Moreinsect mesh for air bricks

...

insect mesh for air bricks 【insect mesh for air bricks】

Read More

insect mesh for air bricksHot dip galvanizing is to remove oil from the workpiece, pickling, dipping, drying after dipping into the dissolved zinc solution for a certain time, can be brought out. Hot dip galvanizing is an effective way to prevent corrosion of metal. It is mainly used for metal structure facilities in various industries. It is to immerse the steel parts after rust removal into the melting zinc liquid at about 500℃, so that the surface of the steel members is attached with zinc layer, so as to play the purpose of anti-corrosion. The galvanized layer is more firm.

...

insect mesh for air bricks 【insect mesh for air bricks】

Read Moreinsect mesh for air bricks

...

insect mesh for air bricks 【insect mesh for air bricks】

Read Moreinsect mesh for air bricks

...

insect mesh for air bricks 【insect mesh for air bricks】

Read More

Popular articles

- When pickling, the galvanized wire needs to be slowly put into the cylinder to avoid liquid splashing on the body. Protective glasses should be worn in the pickling process to prevent acid splash out and hurt people. Pay attention to safety when receiving the line operation, the line tray needs to be lightly placed, stacked neatly, not more than 5 disks. No matter what kind of auxiliary materials are used, galvanized wire drawing must comply with national regulations, otherwise it is not allowed to be used.

- 3. Temporary protection, breeding chickens and ducks, etc., it is recommended that you choose 2mm wire diameter products.

- The screen is made into a box-like container, with stone filled with cages, can be used to protect and support seawall, hillside, road and bridge, reservoir and other civil engineering, flood control and flood resistance is a good material.

Latest articles

-

The uniformity of galvanized wire is reflected in what aspects:

-

Hexagonal mesh is also known as twisting mesh, thermal insulation net, soft edge net. It has strong structure, flat surface, good corrosion resistance, oxidation resistance and so on.

-

-

-

-

Dogs of all ages seem to love to touch their noses with humans and other animals. In fact, dogs touch their noses as a way of socializing, just like humans shake hands and hug when they meet. But dogs don’t touch every human or every animal. They pick and choose who to touch. If they don’t like you or don’t know you at all, they won’t touch your nose. However, adult dogs will touch almost every puppy’s nose, and they will not only touch the puppy’s nose, but also smell it.

Links

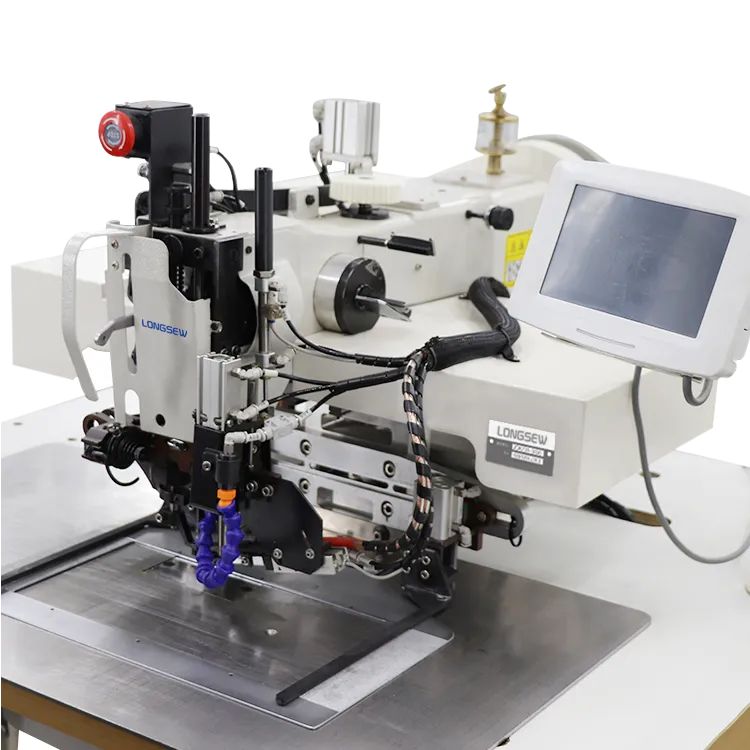

- Don't miss out on this opportunity to take your sewing skills to the next level. Visit our store today to explore our selection of pattern sewing machines for sale and find the perfect match for your needs. Get ready to unleash your creativity and bring your sewing projects to life with a new, high-quality sewing machine from us.

The double stitch machine is more than just a tool; it is a vital component in modern textile manufacturing that shapes the quality and efficiency of production. With its extensive applications, significant advantages, and adaptability to new technologies, the double stitch machine will undoubtedly continue to play a pivotal role in the industry’s evolution. As manufacturers strive to meet the demands of a fast-paced and eco-conscious market, the double stitch machine stands ready to lead the charge towards innovation and sustainability in textile production.

Enhanced Creativity and Versatility

Auto sewing refers to the use of advanced robotics and computerized technology to perform sewing operations with minimal human intervention. Traditionally, sewing was a labor-intensive task, relying heavily on skilled workers to produce garments. However, with advancements in artificial intelligence (AI), machine learning, and robotics, auto sewing systems can now replicate these skills with remarkable precision.